New Products

Find Trapezoidal Panel Making Machinery, Sheet Making Machine, Trapezoidal Panel Sheet Making Machine on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

| Payment Type: | L/C,T/T,Money Gram,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 30 Days |

Model No.: KYT

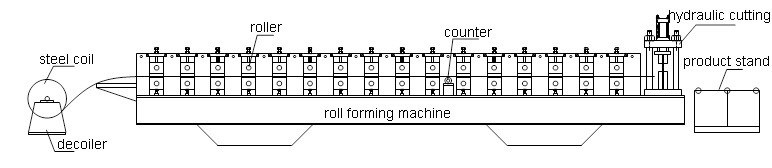

In the modern time , color steel panel is widely used for the factory , warehouse , air port , train station and other building construction .

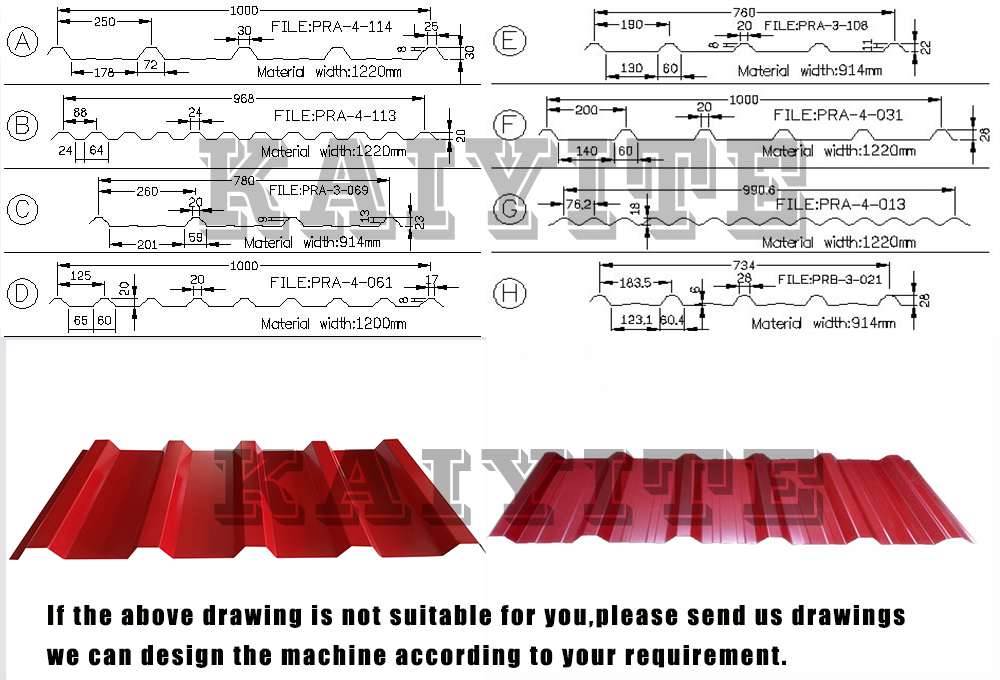

These beautiful and popular roof panel is made by the roofing trapezoidal panel sheet making machinery . The steel sheet feed into the machine , formed by many types of rollers and then form variety of shapes of the machine.

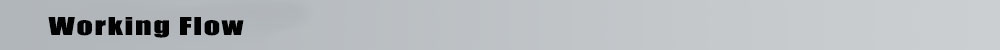

Decoiling the sheet→Sheet guiding→Roll forming→Measure length→Cutting the panel→Panels to product stand

Hydraulic cutting system : Hydraulic Cutting with two Guide Pillars and two cylinders .

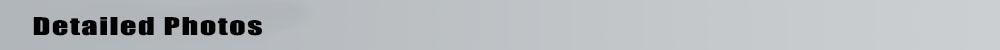

Forming rollers Specification: 45# steel, CNC Lathes, heat treated Feature: hard chrome plating, 0.05 mm

Main frame specification: 400 H steel . Thickness : 16mm feature: More stable, no shaking

Guide device

It is used to control the width and position of the steel sheet.The sheet is guided into the machine with correct position to make sure the panel is neat and parallel.

Manual uncoiler

It is used to support the steel coil and realize the uncoiling by means of rotatory movement. The steel coil is uncoiled manually. The capacity of this uncoiler is 5 ton, and it is capable for most of the coils.

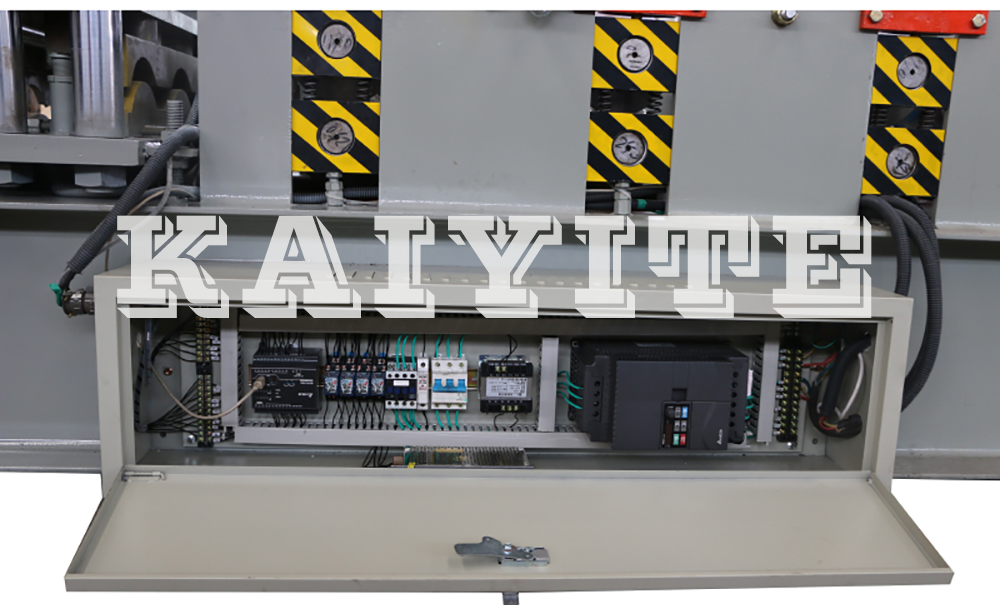

Electrical control cabinet

PLC is adopted to organize all action of the machine. The length of workpiece is adjustable according to the setting of on the PLC. Two optional control modes:Automatic and manual. By automatic mode, the machine can realize fully automatic working .

Hydraulic system

It is drived by a gear pump. After filling the hydraulic oil into the hydraulic oil tank , the pump could drive the hydraulic cylinder to realize the cutting function .The system includes a set of hydraulic tank , a set of a gear pump , two hydraulic pipes and two sets of solenoid valves .

Output Table

It is widely used in village , hotel , exhibition , family construction and outdoor decorage.

A. For this machine need 1*40 GP container to load, one container can load 2 sets machines normally.Before loading to container, we will check and test machine frist.

B. We will make the plastic package on the easy damage parts, paint the oil on the roller and shaft, in case the roller and shaft got corrosion and rusty during long time delievery.

C. we will fix all the parts into container by steel wire rope. And ensure the machine will not damage when shaking on sea.

D. we will take phoots and videos for customer when loading to container, so that the customer can take out the machine easily when receive the goods

The following picture shows the whole production process of the roll forming machine.

We strictly control the quality of everything machine details to satisfy our clients. Quality winns reputation.

Customers satisfaction is our pursuit.

Company Information

Kaiyite machinery is a leading manufacture of roll forming machine . We know well the particular requirements for the customers from different countries , and have an outstanding export team who will take your requests . Our experts and skilled workers complete the work with great precision .

We provide an extensive line of products , including roller shutter door roll forming machine ,door frame machine, roof and wall panel roll forming machine , double layer roll forming machine ,floor deck roll forming machine ,C / Z / U Purlin Roll Forming Machine , stud and track roll forming machine , ridge cap roll forming machine , downspout pipe roll forming machine , shearing machine and bending machine , slitting and cutting machine .

Product Categories : Roof And Wall Panel Roll Forming Machine > Trapezoidal Tile Roll Forming Machine